Function

As a core automotive component, it transmits power from the engine or motor to the wheels. It is engineered to withstand high-speed torque and high power, delivering it without noise or vibration.

Applicable Models

-

Passenger Cars

Sonata, Grandeur, K5

-

SUV

Kona, Niro, Seltos, Sorento, Santafe

-

EV

IONIQ9,EV3, EV5, EV6, EV9, PV5

-

Other

Staria, Dogde Charger, Alfa Romeo stelvio & Giulia Maserati Levante

-

BJ

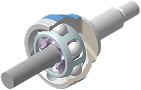

A standard wheel-side joint engineered for superior stability and durability by applying angular contact between the balls and the inner/outer track.

-

EUJ

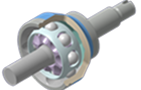

A compact, 8-ball specification of the UBJ that enhances efficiency by reducing heat generation and minimizing torque loss.

-

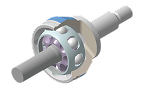

BJc

Engineered to be more compact and lightweight than the BJ specification, while securing identical strength and durability performance.

-

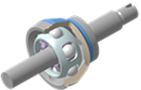

HBJ

This joint features a counter track to achieve a 52° maximum articulation angle, enhancing efficiency by lowering heat generation and minimizing torque loss.

-

UBJ

This joint incorporates an undercut track to realize a maximum articulation angle of 50° and superior strength at high angles.

-

SJ

A dedicated rear-wheel joint incorporating a counter track, which boosts efficiency by reducing heat generation and minimizing torque loss.

-

SUJ

Features a symmetrical undercut track to deliver a maximum articulation angle of 50° along with superior strength and durability at high angles.

-

FCJ

A dedicated rear-wheel joint featuring a cross-groove track that reduces heat generation, torque loss, and backlash.

-

EBJ

A compact, 8-ball specification of the BJ that enhances efficiency by reducing heat generation and minimizing torque loss.

-

TJ

A standard roller-type joint providing exceptional stability and durability.

-

TJC

Engineered to be more compact and lightweight than the TJ specification, while securing identical strength and durability performance.

-

LSJ

A roller kit type joint delivering superior low-vibration and NVH (GAF and PR) performance.

-

HLSJ

Features an improved articulation angle and sealing performance over the LSJ model.

-

DOJ

A ball-type joint equipped with a double offset straight track and a longer stroke than the TJ.

-

EDOJ

A compact, 8-ball specification of the DOJ that enhances efficiency by reducing heat generation and minimizing torque loss.

-

CJ

A joint incorporating a cross-groove track for superior NVH performance and minimized backlash.

-

ECJ

A compact, 8-ball specification of the CJ that enhances efficiency by reducing heat generation and minimizing torque loss.

-

WTS (Friction Welding Tubular Shaft)

30% weight reduction compared to solid shaft, Improvement of NVH performance, High torsional stiffness

-

MTS (Monoblock Tubular Shaft)

40% weight reduction compared to solid shaft, Improvement of NVH performance, High torsional stiffness

-

IDA (Intergrated Drice Axle)

A next-generation hub bearing that integrates the Hub and Halfshaft. Lightweight with high lateral rigidity. IDA Composition: Can be assembled by combining IDA with various joints like ECJ, FCJ, and EDOJ.

-

BSJ (Ball Spline Joint)

Integrates a ball spline design into the inner race of the lightweight, 8-ball SJ / FCJ joint. Maximum articulation angle of 32° and a plunging length of 62mm.