Seohan Group

Great Challenge & Innovation!

Performance and History

- Selected for the World Class+ Project support program Development of a four‑wheel independent‑drive electrification module for future mobility (Ministry of Trade, Industry and Energy)

- Winner of the IR52 Jang Young‑Sil Award (High‑strength constant-velocity joint for electric vehicles with carbon‑reduction technology)

- Prime Minister’s Commendation for Industrial Technology Promotion (New Technology Commercialization category)

- Received NET (New Excellent Technology) certification (Cast Iron H/Disc)

- Certified as a Specialized Company in Materials, Parts, and Equipment

- Received the Technology 5-Star 5★ rating (HMC)

- Received the certification as a company specializing in materials & components

- Received the Technology 5-Star 5★ rating (HMC)

- Received the certification as a company with Excellent job invention compensation

- Developed Damper Fork

- Received the Technology 5-Star 5★ rating (HMC)

- Received the Technology 5-Star 5★ rating (HMC)

- Excellent Product Development Partner Award (HMC)

- IR52 Jang Youngsil Award (Hybrid Disc)

- Developed Aluminum Knuckle & Carrier

- Lightweight Hybrid Disc New Technology Certification (NET)

- Research institute moved (Dongtan)

- Korea’s first LSJ that minimizes lateral vibration developed

- CJ with excellent rotational balance developed domestically

- Established Seohan Engineering Research Institute (Jincheon)

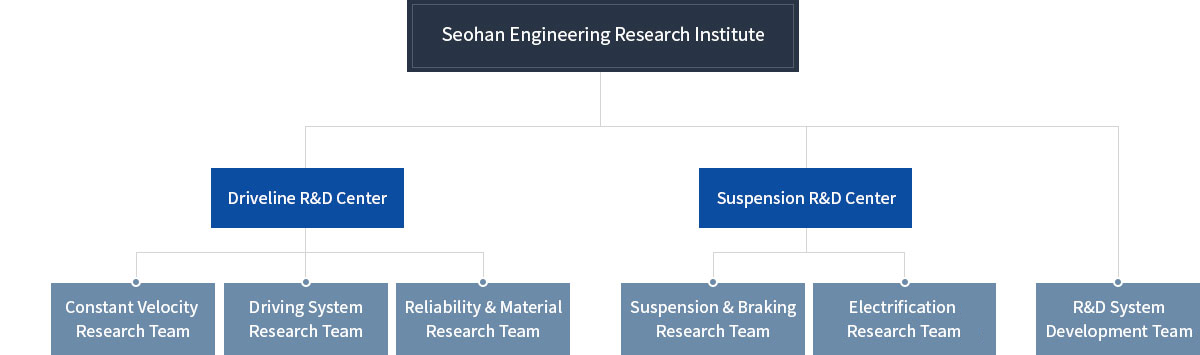

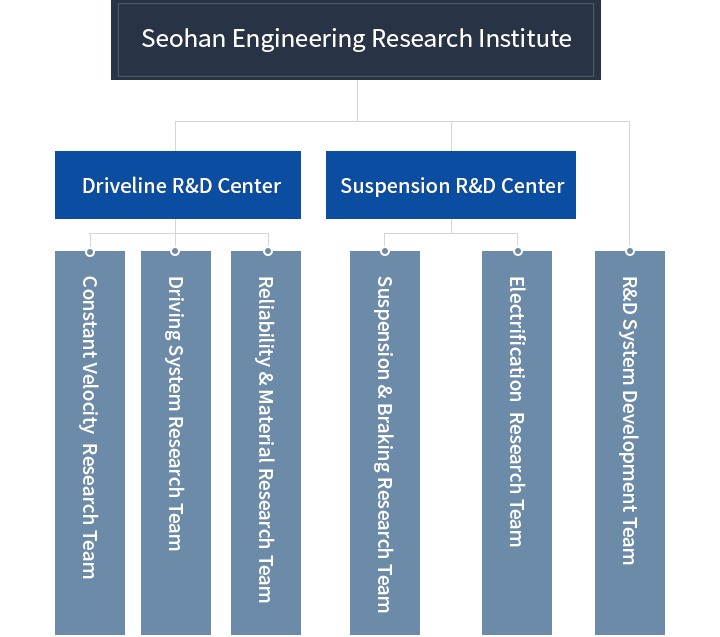

Corporate Organization

-

Research Facilities

Office Building 3,147㎡ / Testing Center 3,150㎡ / Amenities 3,123㎡

Office Building 3,147㎡ / Testing Center 3,150㎡ / Amenities 3,123㎡ -

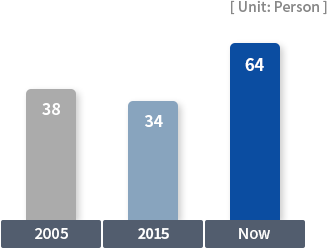

Researchers

-

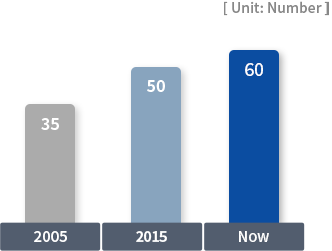

Research Equipment

Research & Development Areas

-

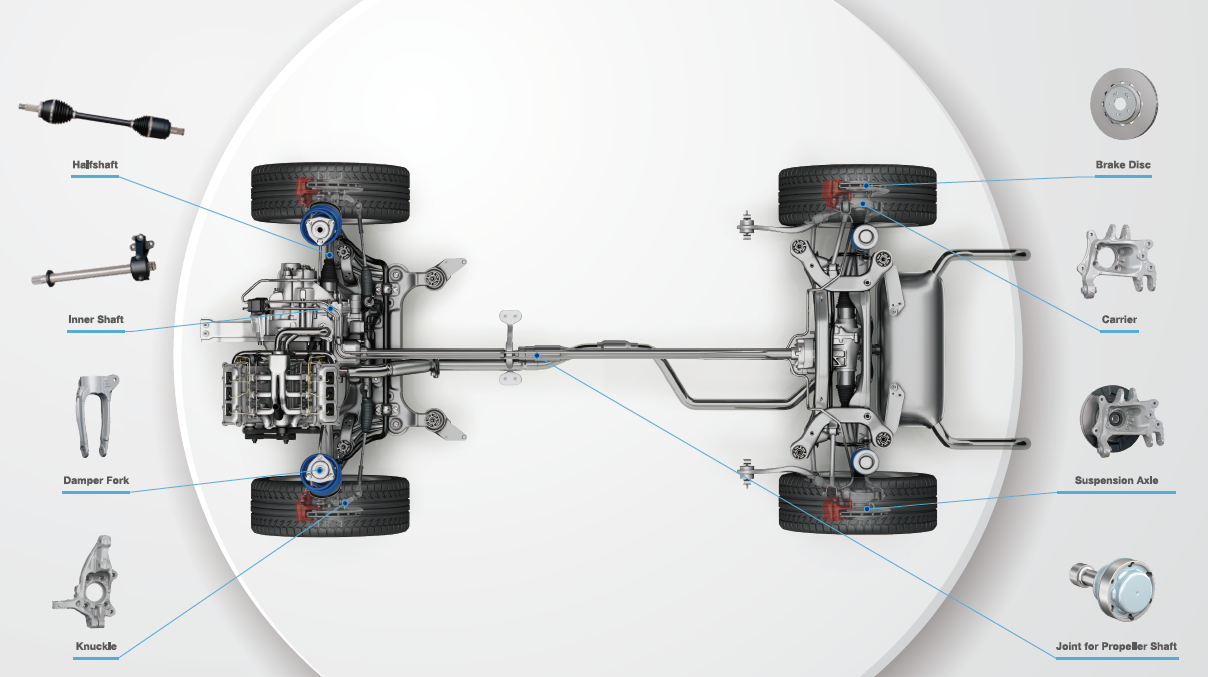

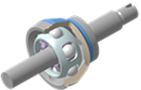

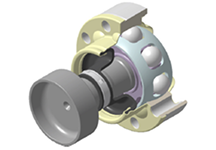

Fixed Joint

-

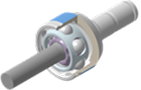

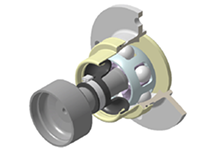

BJ

A standard wheel-side joint engineered for superior stability and durability by applying angular contact between the balls and the inner/outer track.

-

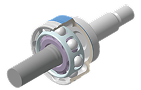

EUJ

A compact, 8-ball specification of the UBJ that enhances efficiency by reducing heat generation and minimizing torque loss.

-

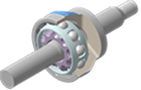

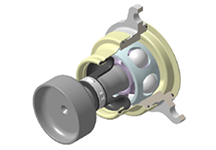

BJc

Engineered to be more compact and lightweight than the BJ specification, while securing identical strength and durability performance.

-

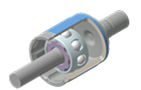

HBJ

This joint features a counter track to achieve a 52° maximum articulation angle, enhancing efficiency by lowering heat generation and minimizing torque loss.

-

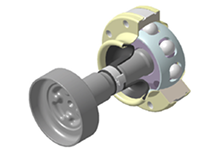

UBJ

This joint incorporates an undercut track to realize a maximum articulation angle of 50° and superior strength at high angles.

-

SJ

A dedicated rear-wheel joint incorporating a counter track, which boosts efficiency by reducing heat generation and minimizing torque loss.

-

SUJ

Features a symmetrical undercut track to deliver a maximum articulation angle of 50° along with superior strength and durability at high angles.

-

FCJ

A dedicated rear-wheel joint featuring a cross-groove track that reduces heat generation, torque loss, and backlash.

-

EBJ

A compact, 8-ball specification of the BJ that enhances efficiency by reducing heat generation and minimizing torque loss.

-

-

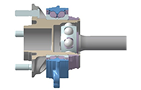

Plunging Joint

-

TJ

A standard roller-type joint providing exceptional stability and durability.

-

TJC

Engineered to be more compact and lightweight than the TJ specification, while securing identical strength and durability performance.

-

LSJ

A roller kit type joint delivering superior low-vibration and NVH (GAF and PR) performance.

-

HLSJ

Features an improved articulation angle and sealing performance over the LSJ model.

-

DOJ

A ball-type joint equipped with a double offset straight track and a longer stroke than the TJ.

-

EDOJ

A compact, 8-ball specification of the DOJ that enhances efficiency by reducing heat generation and minimizing torque loss.

-

CJ

A joint incorporating a cross-groove track for superior NVH performance and minimized backlash.

-

ECJ

A compact, 8-ball specification of the CJ that enhances efficiency by reducing heat generation and minimizing torque loss.

-

-

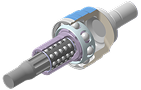

Hollow Shaft

-

WTS (Friction Welding Tubular Shaft)

30% weight reduction compared to solid shaft, Improvement of NVH performance, High torsional stiffness

-

MTS (Monoblock Tubular Shaft)

40% weight reduction compared to solid shaft, Improvement of NVH performance, High torsional stiffness

-

-

Joints for Propeller shaft

-

Disc CJ (Cross groove Joint)

- Maximum articulation angle: 4°

- Superior NVH performance

- Lightweight & compact design

-

Disc BJ (Birfield Joint)

- Maximum articulation angle: 7°

- Suitable for high-speed rotation and high-angle vehicle models

- Compact design applying a J-shaped boot

-

Monoblock CJ (Cross groove Joint)

- Maximum articulation angle: 4°

- Superior NVH performance

- Cost-effective and weight-reduced specification

-

Flange BJ (Birfield Joint)

- 4-hole flange specification

- Suitable for high-speed rotation and high-angle vehicle models

- Compact design applying a J-shaped boot

-

Flange CJ (Cross groove Joint)

- 3-hole flange specification

- Optimized for vehicle assembly process

- Lightweight design compared to the disc specification

-

Disc HBJ (High efficiency Birfield Joint)

- 8-ball compact design

- High-torque and high-efficiency specification

- Superior durability from low heat generation

-

DCJ (Direct Connecting Joint)

- 8-ball monoblock design

- Excellent backlash performance

- Spline structure for direct assembly to the vehicle

-

Disc PSJ (P/Shaft Symmetric offset Joint)

- 8-ball compact design

- Features a symmetrical track structure

- Superior durability from low heat generation

-

-

New Joints for Halfshaft

-

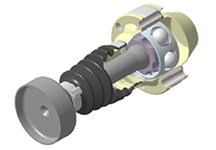

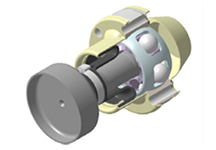

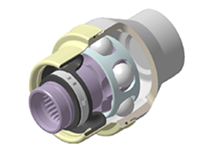

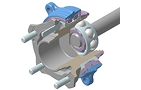

IDA (Integrated Drive)

A next-generation hub bearing that integrates the Hub and Halfshaft. Lightweight with high lateral rigidity. IDA Composition: Can be assembled by combining IDA with various joints like ECJ, FCJ, and EDOJ.

-

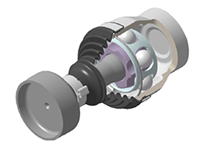

BSJ (Ball Spline Joint)

Integrates a ball spline design into the inner race of the lightweight, 8-ball SJ / FCJ joint. Maximum articulation angle of 32° and a plunging length of 62mm.

-

-

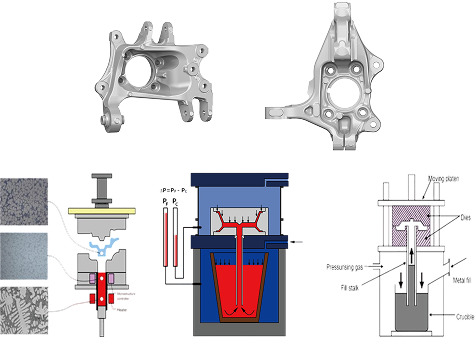

Aluminum Knuckle & Carrier

Casting methods (high pressure, counter pressure, low pressure)

Securing product competitiveness through diversification of manufacturing processes

-

Disc Machining & Surface Treatment

New machining process for braking surfaces

New surface treatment process

-

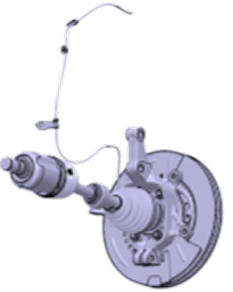

Modularization

Axle & Halfshaft, Axle & Brake Complete, Integrated Axle

Improved system performance

New system structure

-

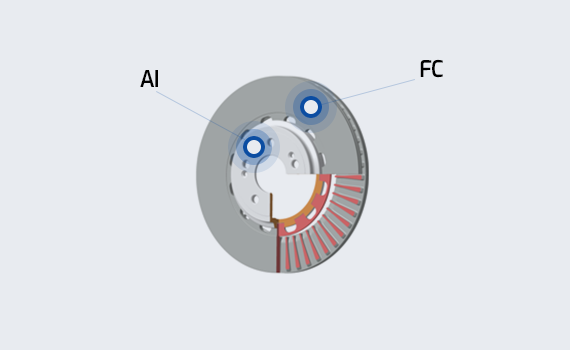

All-Aluminum Disc Development

Achieves 50% weight reduction through all-aluminum construction, adapting to the future vehicle environment.

-

Aluminum Hybrid Disc Development

Realizes improved fuel efficiency and ride comfort by applying aluminum to the mounting area for weight reduction.

-

Cast Iron Hybrid Disc Development

Responds to the demands of EV platforms by improving strength and reducing weight through material changes.

-

Nitrided Disc Development for Rust Prevention

Achieves improved disc lifespan and functional enhancements through the development of a surface-nitrided disc.

Achievements of Research

-

94Patents registered in Korea

94Patents registered in Korea -

10Patents registered internationally

10Patents registered internationally -

37Domestic and international applications

37Domestic and international applications -

4Designs

4Designs